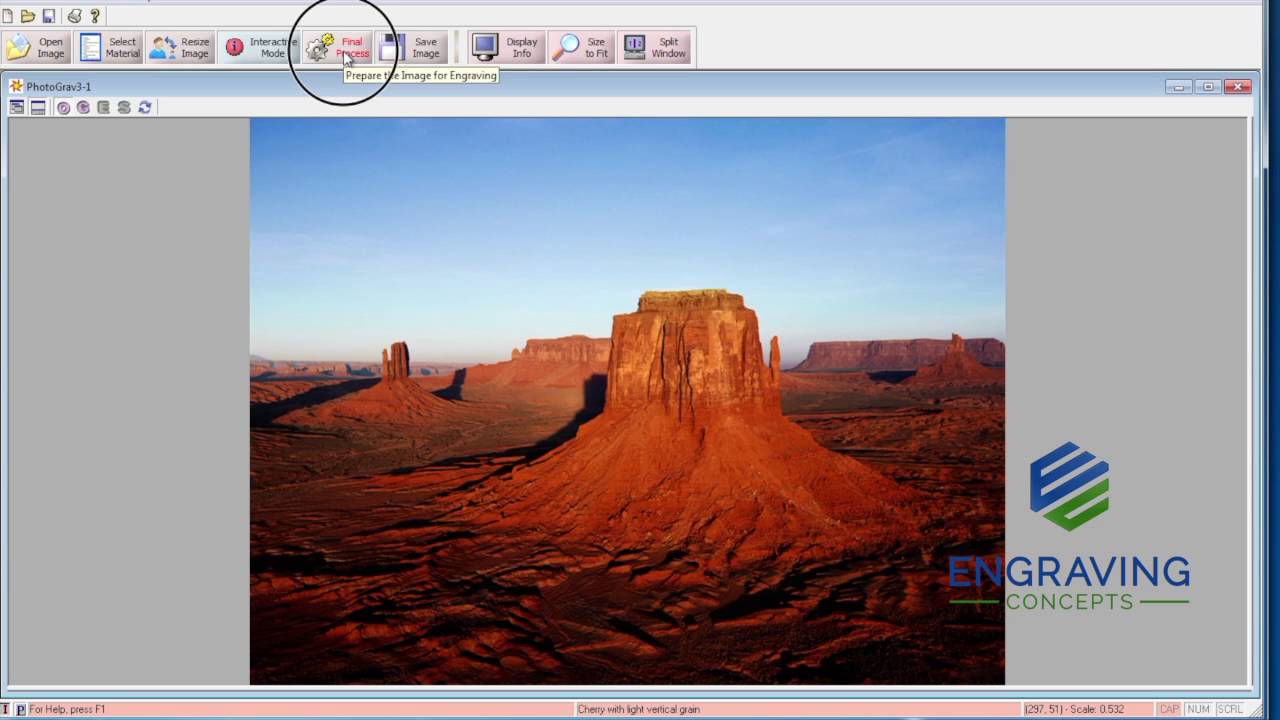

However, it’s only compatible with laser engravers that have GRBL controllers. With this, you can load any kind of image, including photos, clip art, pencil drawings, and icons into LaserGRBL and turn it into g-code without any additional software. There’s also the override function, which allows you to speed up or slow down the effective engraving speed and laser power in real-time during the engraving process.Īnother notable feature is the raster image import function. LaserGRBL has some really useful features, such as the jogging feature that allows you to manually position the laser head with two sliders to control the size and speed of steps.

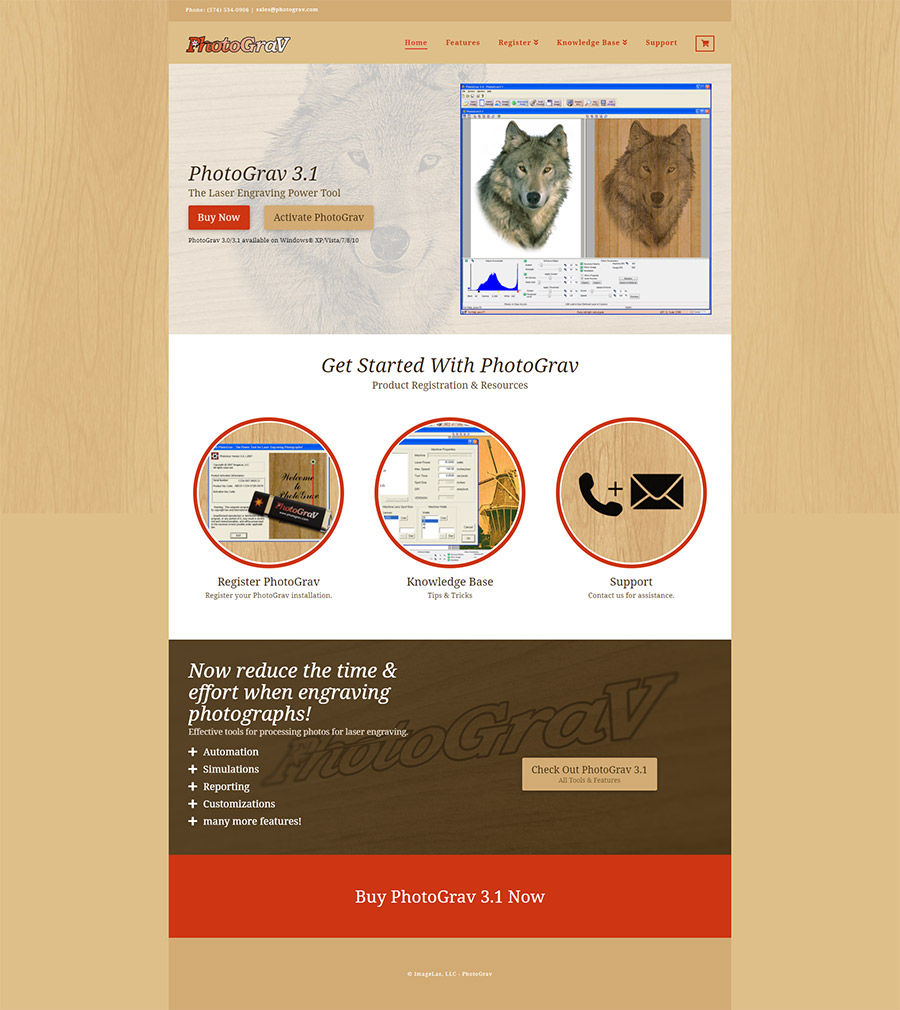

The UI is easy to use, without many confusing options, as you can see in this screenshot below: It’s specifically designed for hobbyists, so it’s a user-friendly tool perfect for beginners, and having used it in my laser projects, I rate it as the best free laser engraving software. LaserGRBL is an open-source laser engraver software for Windows that’s completely free to download and use. Only compatible with lasers that have GRBL controllers. The main factors to consider are obviously price, but also think about compatibility with your operating system (for example, LaserGRBL doesn’t work with MacOS), compatible file formats (beyond SVG, do they support AI, PDF, DXF), and the features you need (for example, built-in air assist or rotary attachment support). In another article we covered how the best nesting software work at reducing material waste. We’ll cover beginner-friendly control software like LaserGRBL and Lightburn, as well as more technical raster and vector designers like Illustrator and Inkscape.

I’ve used many of the most popular laser engraving software with my laser cutters, and this guide will compare my hands-on experience so you can decide which is right for you You’ll need software to create and edit your designs prior to the engraving process, but how do you know which is the best laser cutting and engraving software for you? Laser engraving isn’t controlled manually - it relies on laser cutting software that instructs the laser where to move using g-code.

0 kommentar(er)

0 kommentar(er)